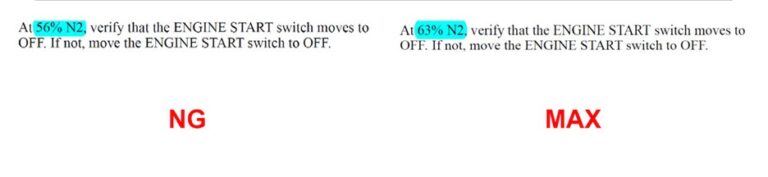

The Bowed Rotor Motoring (BRM) performed by EEC is the main difference between the NG and

MAX (motor CFM Leap 1B) engine start procedures. While the crew moves the Engine, start

switch to GND, BRM (Bowed Rotor Motoring) begins straightening the N1 and N2 rotor shafts.

When the engines are turned off, the thermal build-up allows the N1 and N2 rotor shafts to bow.

What is bowing effect?

Rotor bowing, also known as thermal bowing, is caused by asymmetrical cooling after the

previous flight’s shut-down. The hot air from the metal components increases inside the motor

and the upper part of the compressor cools more slowly than the lower part, so the upper part

of the compressor expands more, while the colder lower part causes the compressor to bend,

which is called a rotor bow.

Slower starting allows more even heating, eliminating differential thermal deformation.

BRM is active for 6-90 seconds on the ground only.

Displayed (white) – Bowed Rotor Motoring (BRM) logic is active during engine start on the

ground.

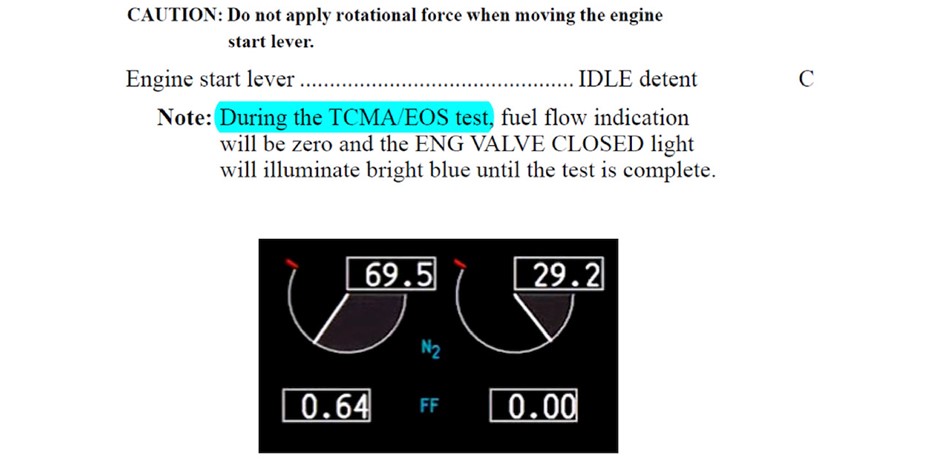

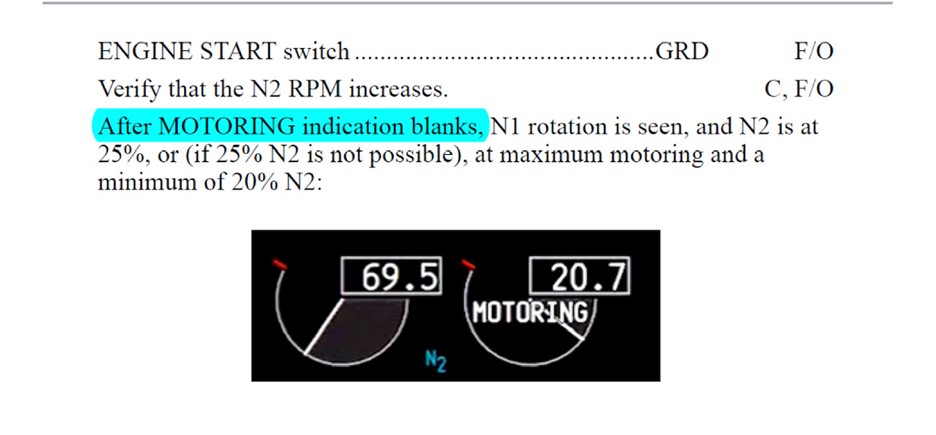

Motoring is shown on the N2 gauge between 18 and 24 percent N2 during BRM. EEC tests the

TCMA (Thrust Control Malfunction Accommodation) and EOS after the engine accelerates to the

recommended value (25 percent N2 or max motoring) and the “motoring” disappears by pushing

the engine start lever to the IDLE position (Electronic Overspeed System).

At starter cutout speed approximately 63% N2, power is removed from the start switch holding solenoid.

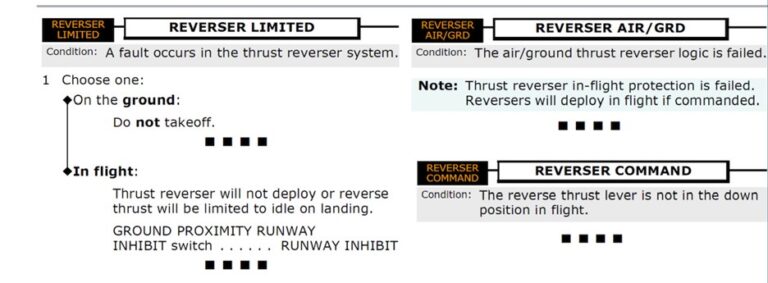

The engine start switches return to OFF. We offer some images related with Preflight and Postflight Scan

flow, Engine Start Procedure, Normal Procedures and Engines, APU- REVERSER NNCs.